PDR Guide

Can PDR Fix Body Line Dents?

FSDAVCFEBFEVSDDVFSD

FSDAVCFEBFEVSDDVFSD

FSDAVCFEBFEVSDDVFSD

Body lines versus flat panels explained

Not all dents behave the same. Body line dents sit on sharp styling creases, where metal is stronger but quicker to stretch. Flat-panel dents, like typical hail impressions, spread force across a broader area. Knowing the difference guides whether paintless dent repair keeps your factory finish intact.

At Dentex Midwest, our technicians assess metal stretch, ridge sharpness, and surrounding crowns before touching tools. We choose between precision pushing from behind, glue-pull sequences, and tap-down shaping that releases pressure. That triage determines true PDR feasibility versus a push-to-paint decision when coatings or structure are already compromised today.

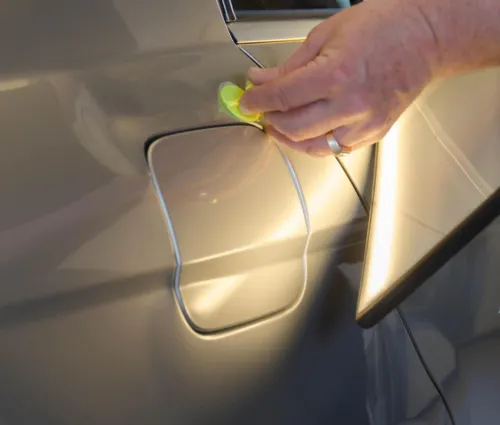

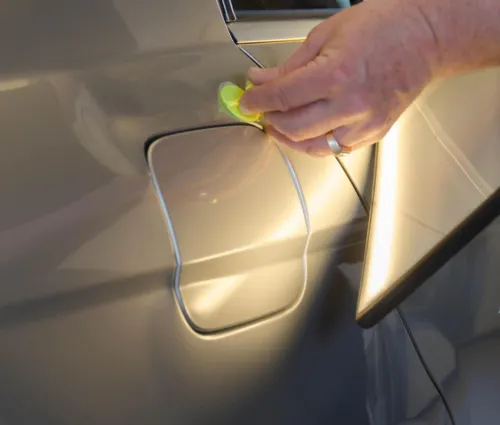

Techniques that protect factory finishes

Body lines are work-hardened creases stamped into the panel. When they dent, energy funnels into a tight ridge that can “oil can” if mishandled. The fix isn’t brute force; it’s micro movement. We map tension with PDR lights, identify crowns, and sequence relief taps so the ridge relaxes before we lift lows and stabilize the surrounding metal.

On flat panels, impacts distribute load widely. Instead of a hard ridge, you get smooth bowls and soft crowns. Here the dance changes: we prefer controlled glue pulling first, stepping up tab size and force gradually, then pushing from access points with soft tips. Each pull is balanced by strategic tap-downs to avoid highs and paint stress.

Both paths rely on reading steel or aluminum behavior, not rushing. Panel gauge, brace layout, e-coat health, and paint flexibility all matter. Our technicians document each stage for insurer visibility and for you, showing why body line dent PDR demands patience while flat panel hail dent work favors tempo without sacrificing finish, structure, or alignment integrity.

Feasibility signals you can spot

Start with the paint. If you see spider cracks, lifted clear, or sharp chips on the ridge, pure PDR is unlikely. Next, check sharpness: the tighter the kink right on the body line, the more metal stretch we must reverse. Finally, look for displaced crowns spreading out several inches from impact. Those crowns store energy that will fight the repair if left unmanaged.

Inside the panel, bracing changes access and tool leverage. Some trucks have double-wall structures along character lines; sedans may hide airbags, sensors, or foam. We scan, remove trim as needed, and test flex with a soft tip before committing. Good access lets us push surgically. Poor access shifts us toward glue pulling, especially when finishes are fragile or access holes are prohibited entirely.

Precision pushing is our scalpel for body line creases. Using rigid rods and ultra-sharp tips, we lift metal in microscopic steps from the strongest part of the line outward. Every nudge is checked under LED reflection to avoid peaking. Between pushes, a polished tap-down softens crowns and resets tension gradients. This keeps the ridge defined, not wavy, and preserves paint elasticity. We advance only when the panel relaxes across the crease and flats.

Glue pulling shines on flat-panel hail dents and when tool access is blocked. We choose tabs that match the dent’s footprint, modulate pull strength, and immediately balance tension with tap-downs. On creases, we may alternate pull directions to narrow the valley before finishing with controlled pushes. Sequencing matters; aggressive early pulls can spike highs or fracture brittle clear, so we build results in layers while monitoring temperature and adhesive behavior through each cycle.

When PDR isn’t the answer

Sometimes the smartest repair is push-to-paint. If paint is cracked on a body line, finishing with conventional refinishing protects the panel from corrosion and restores appearance. We’ll still perform controlled pushing to reduce filler depth and preserve shape. The goal is structural soundness and minimal repaint footprint, not forcing pure PDR when longevity is the priority anyway.

Extreme stretch is another red flag. If the crease edges feel thin or the ridge shows a knife-like hinge, the metal has yielded beyond elastic recovery. On these, we’ll advise blending PDR reduction with paint to avoid overworking. Pushing too far invites micro fracturing or oil canning that undermines long-term results and may compromise safety margins later.

Lastly, access limitations can set boundaries. Some body lines are boxed by crash structures, curtain airbags, or double walls. If creating access holes isn’t appropriate, we rely heavily on glue, but a perfect finish may be unrealistic. We’ll set expectations clearly and recommend the path that protects value on Missouri roads through seasons, salt, and sun.

Reading crowns like a map

Crowns are the raised tension rings circling a dent. Pushing the low too soon traps energy. We soften crowns first, tapping from perimeter inward. As stress releases, each push needs less force and reflections tighten along the line.

On flat panels, crowns are broader and lighter. We chase them with tips and taps, keeping the panel mobile. This prevents the center from rising into a high. The result is smoother shape recovery without texture telegraphing clearcoat.

Readings come from lights, not guesses. LED boards exaggerate distortion so imperfections pop early. As lines straighten, tension leaves. That precision makes crease dent repair predictable, especially on Missouri vehicles that endure heat swings and winter and storms.

Aluminum complicates the picture. It work-hardens faster, transmits heat differently, and springs more than steel. We temper techniques accordingly: smaller pushes, more crown reduction, and careful temperature control to keep coatings pliable. Body line dent PDR on aluminum is feasible, but it demands added patience, longer stays under lights, and disciplined sequencing. We verify alloy and thickness, confirm access, and brief you and insurers on timelines and finish expectations so approvals and scheduling stay smooth end-to-end.

Examples from recent Missouri storms

After a spring hailstorm in O’Fallon, a Silverado arrived with a razor crease along the cab body line. Paint was intact. We sequenced crown reduction, then ultra-sharp pushing from behind the brace, finishing with glue pulls on the valley. The ridge re-formed straight. Under lights, texture returned and the truck left with original paint, zero filler, and an insurer-approved supplement reduced because we avoided R&I on the opposite side entirely.

A second case in Arnold involved a Camry struck on the door body line by a wayward shopping cart. Sharpness was high and paint fractured at the hinge. We recommended push-to-paint. After reducing the crease footprint with precise pushes and controlled glue pulls, conventional refinishing restored gloss. The owner gained a straighter substrate, minimal filler, and a smaller blend zone thanks to the PDR prep work preceding paint application beautifully.

A third example: a Florissant SUV with dozens of flat panel hail dents across roof and hood. We staged the job around lighting and temperature, ran glue-pull rounds, and alternated soft-tip pushes where access existed. Sequenced tap-downs prevented highs. Results: uniform reflections, preserved e-coat, and no repainting. That efficiency shortened rental days and earned quick insurer approval while keeping Missouri paintless dent feasibility high for future storms across the region.

Dentex Midwest

Professional Hail Repair & PDR

Stay Up-to-date With Our Content

Subscribe to learn more about our mission!

Stay Up-to-date With Our Content

Subscribe to learn more!

Contact Info

Service Hours

Social Media

Home

Services

Service Areas

Blog

About

Contact

Contact Info

Service Hours

Mon - Fri: 8:00 am – 6:00 pm

Saturday: by Appointment

Sunday: Closed

Social Media

Licensed, bonded, & insured